What is a bill of materials

A bill of materials (BOM) lists all the parts, pieces, assemblies, subassemblies, intermediate assemblies, paperwork, drawings, and other materials to make a product. The BOM, given in a hierarchical style, can be viewed as the recipe for creating a final product. The bill of materials and accompanying records list the items needed to source and design an assembly. Regardless of their sector, all product builders launch by producing a bill of materials (BOM).

Since the BOM guides favorable results as products progress from design to development and volume manufacturing, it’s vital to generate and communicate an accurate and up-to-date version with all teams.

It’s also crucial for companies that rely on supply chain collaborators to preserve effective revision control throughout the new product development process. The bill of materials should always be the most recent revision when shared with a manufacturing team to avoid unnecessary production problems and product launch delays.

What a BOM Should Contain

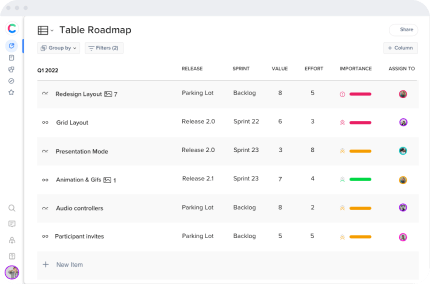

Since one of the BOM’s primary responsibilities is to guarantee that the product is manufactured correctly, including specific product data in the BOM record is essential. Here is a high-level list of information in your BOM record, whether you are writing your first bill of materials or searching for methods to enhance it.

Use BOM Level

Assign a number to each part or assembly to indicate where it belongs in the BOM hierarchy. Anyone who understands the BOM structure can readily interpret the bill of materials this way.

Use Part Number

Assign a part number to each part or assembly so that you can readily refer to and identify it. Manufacturers frequently select between an intelligent and a non-intelligent part numbering scheme. Make sure you don’t create duplicate component numbers for the same part, regardless of your system.

Use Part Name

Make a note of each party’s or assembly’s unique name. This will make it easier to identify parts. Record what stage of the lifetime each element is in. A phrase like ‘In Production’ is commonly used to denote the stage of a portion in production. ‘Unreleased’ or ‘In Design’ refers to new parts that have not yet been approved. This is helpful during a new product takeoff since it helps trace progress and generate logical project calendars.

Also, provide a clear description of each part so that you and others may readily distinguish between similar parts and identify unique ones.

Quantify

To help guide purchasing and production decisions and activities, keep track of the number of parts utilized in each assembly or subassembly. Classify the measurement in which a part will be used or purchased as a unit of measure. The term ‘each’ is commonly used; however, you can also use standard sizes such as inches, feet, ounces, and drops. Maintain consistency across all similar part types because this information will aid in procuring and delivering the correct quantity to the production line.